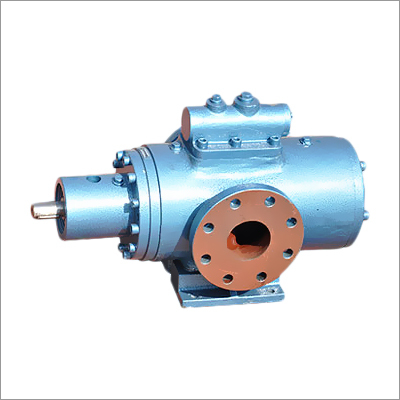

Triple Screw Pump

Product Details:

- Material Single Screw Pumps

- Structure Single Stage Pump

- Power Hydraulic Watt (w)

- Pressure Medium Pressure

- Click to View more

Triple Screw Pump Price And Quantity

- 10000-5000000 INR/Unit

- 1 Piece

Triple Screw Pump Product Specifications

- Medium Pressure

- Single Screw Pumps

- Single Stage Pump

- Hydraulic Watt (w)

Triple Screw Pump Trade Information

- 10 Piece Per Month

- 1 Week

- All India

Product Description

Catering to diverse requirements of clients, we have been engaged in manufacturing and exporting an extensive range of Triple Screw Pump. These pumps are extensively used for hydraulic elevators, machinery lubrication, fuel oil transport, refinery processes and powering hydraulic machinery. Ideal for pumping high temperature viscous products such as vacuum tower bottoms, asphalt and residual fuel oils, the entire range of Triple Screw Pump is offered to clients at competitive prices.

Application Area of Triple Screw Pump:

- Internal or External Bearing Design Available

- Turbulence free pulsation less flow

- Pumps suitable for low NPSH

- Replaceable Cartridge Construction

- Noiseless operation

- Low Maintenance

- Long life

- Orientation of inlet / outlet to meet specific requirement

- Variety Of Casing Material Available

- Variety Of Sealing Arrangement Possible

- Variety Of Mounting Arrangement Possible

Additional Information:

Item Code: Model-PDS

Triple Screw Pumps with internal and external bearing are offered in vertical or horizontal constructions, without or with the arrangements of heating and have single mechanical seals for the sealing of shaft. These shafts handle all the neutral lubricating liquids, are self-priming and have a compact space saving design. Owing to the accurate manufacturing of the profile of the screws, the possibility of having a high suction lift is guaranteed. These pumps run noiselessly and without any hassle.

Principle of operation

There are three screws in the pumping element of the Triple Screw Pumps. The drive or main screw and the two driven screws form transfer chambers by meshing together within the pump.

When the main screw is turned, the chambers move axially and continuously from the side of suction to the discharge side as per the screws pitch. The volume of the various chambers is constant which assures that a constant flow is obtained over the length of the elements of pumping.

The compensating piston completely balances the resulting axial thrust during operated through the main screw. There is a valve relief arranged between suction chamber and seal housing. Balancing bushes or bearings lead the driven screws in the area of discharge. The balancing bushes are only partially balanced. A very low thrust of the axial positions them by moving on to the end plate. Owing to the seal housing suction pressure, i.e., in front of compensating bushes and pistons, the pressure is perfectly balanced.

The screws are in contact with the surrounding casing and as well as each other. Afterward, the medium definitely has to have certain lubrication properties. The normal force between the parts of the component is directly proportional to the medium viscosity. Maximum pressure which is accomplished by the pumps is also directly proportional to the matching viscosity.

Features and Advantages of Triple Screw Pump

- External or Internal Bearing Design Available.

- Long life

- Low Maintenance

- Noiseless operation

- Orientation of outlet/ inlet to match specific requirement

- Pumps compatible for low NPSH

- Replaceable Cartridge Construction

- Less flow Turbulence free pulsation

- Selection Of Casing Material Available

- Selection Of Mounting Arrangement Possible

- Selection Of Sealing Arrangement Possible

- Highly efficient

- Self-priming pump

- Integrated with variable speed drives

Size | Customised |

Driven Type | Electric |

Model | PDS |

Type | Screw Pump |

Specification :

Model | |

Brand | UT Pumps |

Material | Metal |

Frequency | 50 Hz |

Voltage | 415 V |

Usage/Application | Liquid or Paste Transfer |

Size | Standardized |

Max Pressure | 60 Bars |

Max Capacity | 138 m3/Hr. |

Max Temperature | 150 Degree C |

Technical Details

Size | Capacity Flow (m3/Hr) | G(Large Pitch) | H(Normal Pitch) | K(Small Pitch) |

|---|---|---|---|---|

25 | 1.58 | 75 | 90 | 120 |

32 | 3.30 | 75 | 90 | 120 |

38 | 5.55 | 75 | 90 | 120 |

45 | 9 | 75 | 90 | 120 |

52 | 14.25 | 75 | 90 | 120 |

60 | 22.2 | 75 | 90 | 120 |

70 | 35.7 | 75 | 90 | 120 |

80 | 53.4 | 75 | 90 | 120 |

90 | 75.6 | 75 | 90 | 120 |

100 | 103.2 | 75 | 90 | 120 |

110 | 138 | 75 | 90 | 120 |

Other Products in 'Screw Pumps' category

- 14/7, Mathura Road, Faridabad - 121001, Haryana, India

- Phone : 08045804385

- Mr Atul Gupta (VP - Marketing)

- Mobile : 08045804385

- Send Inquiry

|

UT PUMPS & SYSTEMS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |